Have you ever been curious how a smart phone knows which way it is (or isn’t) oriented when taking pictures? Or how auto pilots in ships or aircraft keep the vessel upright? Or how rockets, and orbiting satellites are guided into space? Or how computers are so easily able to show the 1st down line on televised football games while the cameras are in motion? Devices called gyroscopes provide each of these systems their orientation with respect to earth.

Have you ever been curious how a smart phone knows which way it is (or isn’t) oriented when taking pictures? Or how auto pilots in ships or aircraft keep the vessel upright? Or how rockets, and orbiting satellites are guided into space? Or how computers are so easily able to show the 1st down line on televised football games while the cameras are in motion? Devices called gyroscopes provide each of these systems their orientation with respect to earth.

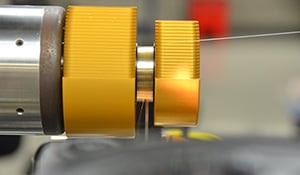

What started out as a spinning wheel on an axis that could move freely and independent in one or two of the other axes, has expanded into several different types of gyros. One of the most accurate types is the Fiber Optic Gyroscope (FOG). A FOG comprises a coil of up to five kilometers (3.1 miles) of glass optical fiber that is wound onto a bobbin or mandrel in varying and complex patterns. The angular rotation of the FOG is measured using a beam of light that is split and then sent through the optical fiber from opposite ends and recombined and then recombined. After recombination, a detector measures the phase of the two light beams, which varies with the rate of rotation of the FOG – a process called the Sagnac effect.

In order to accurately measure rotation, the coil must be wound with very stringent tension and positional requirements. These requirements are what enable FOGs to be so accurate, but at the same time so difficult to manufacture. Manual methods for winding precision FOG coils require many hours (or even days or weeks) to complete a single coil and often result in low yields in addition to high labor costs.

Fraunhofer USA- CMI has developed a FOG coil winding system that significantly reduces the time for winding while improving yield and performance. This system, incorporating both sophisticated hardware and software algorithms, can accurately wind the base-layer and subsequent layers, at any given spacing, from fully compressed (~99-100% fiber diameter) to completely loose (>200% fiber diameter) on a smooth mandrel, with low consistent tension throughout the coil. Each of these strategic grade winding systems are custom tailored for the client’s unique specifications. System features and capabilities include:

- Hardware capable of winding thread, level, bipolar, quadrupole, and octupole patterns

- Accurate <10 micron fiber placement

- Active <10 gm tension control during fiber placement

- Real-time coil inspection with a tracking vision system

Please contact Bill Mosolgo at Fraunhofer USA-CMI if you’d like to learn more.