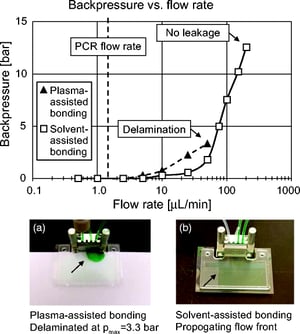

A reduced channel height in microfluidic Lab-on-a-Chip (LOC) devices enables a reduction in the required volume of sample and reagents. LOC devices are most often manufactured by microstructuring a planar substrate and subsequently sealing it with a cover film. However, shallow chip designs, made from polymers, are sensitive to channel deformation during the sealing of the microfluidic device. Inappropriate bonding conditions often result in the loss of the microfluidic functionality. A systematic and practical approach for the identification of suitable bonding process  parameters is missing. In this article, a straightforward approach for the optimization of channel integrity in the sealing of shallow microfluidic devices made from Cyclic Olefin Polymer (COP) is presented. Two COP materials were tested: COP Zeonex 690R (Glass transition temperature Tg = 135 °C) both as a cover film and substrate material, and COP ZF14 (Tg = 135 °C) as a film material. A mechanical analysis using microstructured Zeonex 690R substrates was performed to generate a matrix of low-distortion bonding parameters, including temperature, pressure and time. The well-established method of solvent-assisted bonding was used to enhance the characteristically low bond strengths of the native COP material. In addition, plasma-assisted bonding was tested and compared. The optimization approach was validated by the manufacture of a microfluidic test device, the demonstration of its microfluidic functionality, and the quantitative evaluation of the achieved channel integrity.

parameters is missing. In this article, a straightforward approach for the optimization of channel integrity in the sealing of shallow microfluidic devices made from Cyclic Olefin Polymer (COP) is presented. Two COP materials were tested: COP Zeonex 690R (Glass transition temperature Tg = 135 °C) both as a cover film and substrate material, and COP ZF14 (Tg = 135 °C) as a film material. A mechanical analysis using microstructured Zeonex 690R substrates was performed to generate a matrix of low-distortion bonding parameters, including temperature, pressure and time. The well-established method of solvent-assisted bonding was used to enhance the characteristically low bond strengths of the native COP material. In addition, plasma-assisted bonding was tested and compared. The optimization approach was validated by the manufacture of a microfluidic test device, the demonstration of its microfluidic functionality, and the quantitative evaluation of the achieved channel integrity.