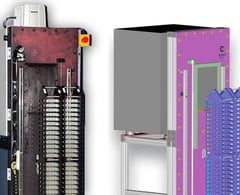

Custom Automated Microtiter Plate Loading / Unloading and Logging for Luminescent Image Analysis

Customer

A large pharmaceutical company

Objective

In the field of drug discovery, assays must be custom automated to achieve the required high throughput analysis for screening new drug candidates. A large pharmaceutical company contracted Fraunhofer USA CMI to develop custom automation for the loading/unloading, handling, and data logging of microtiter plates into a commercial Luminescent Image Analyzer in order to increase the throughput of their screening assays. In addition, a primary design requirement necessitated a very small footprint to be compatible with the crowded and expensive laboratory environment.

Technical Summary

The unique custom automation system reduced the number of part "handoffs" thereby increasing reliability while reducing cycle time. The entire load/unload mechanism, including the storage magazine, were all attached to what became a new door on the imaging chamber. Microtiter plates are then picked up from the storage magazine using the integral load/unload mechanism. This mechanism also holds the plate during imaging, similar to a CD / DVD drive, thereby reducing the number of handoffs. The imaging results are logged by the control computer and a bar code reader helps ensure traceability and scheduling of hundreds of samples daily.

Results

- Capacity for 50 microtiter plates that can be replenished on the fly

- Changeover time of less than 10 seconds

- Two removable storage magazines for remote loading

- Unattended operation

- Simple retrofit to existing systems

- Bar code reader reduces errors in identification and data collection

- No increase in footprint