Renewable Energy

Renewable energy is a relatively new and growing industry, and as such, unique challenges are encountered along the path to commercialization. Whether those challenges are in system design, component design, cost-effective manufacturing, or automated inspection, Fraunhofer USA CMI has the depth of technical experience to raise your program's success to the next level. Past projects have included contributions to solar, wind, and wave energy.

Renewable energy is a relatively new and growing industry, and as such, unique challenges are encountered along the path to commercialization. Whether those challenges are in system design, component design, cost-effective manufacturing, or automated inspection, Fraunhofer USA CMI has the depth of technical experience to raise your program's success to the next level. Past projects have included contributions to solar, wind, and wave energy.

Fraunhofer CMI has a unique combination of expertise that includes both engineering and biological sciences. We are one of the few places where our staff can engineer devices and instrumentation in our own machine shops, then walk across the hall and hand them to the biologists and chemists developing novel assays in our biosafety level one and two laboratories. We leverage our expertise in engineering design and biological sciences to develop cutting edge solutions for the biotech/biomedical community. We are highly active in the areas of microfluidics, point-of-care in-vitro diagnostics, biosensors, medical devices, tissue engineering, and laboratory automation. Our devices and systems range in scale from the nanoscale to the automation of factories.

Fraunhofer CMI has a unique combination of expertise that includes both engineering and biological sciences. We are one of the few places where our staff can engineer devices and instrumentation in our own machine shops, then walk across the hall and hand them to the biologists and chemists developing novel assays in our biosafety level one and two laboratories. We leverage our expertise in engineering design and biological sciences to develop cutting edge solutions for the biotech/biomedical community. We are highly active in the areas of microfluidics, point-of-care in-vitro diagnostics, biosensors, medical devices, tissue engineering, and laboratory automation. Our devices and systems range in scale from the nanoscale to the automation of factories. Fraunhofer USA CMI solves the challenges of manufacturing high volume consumer products in today's economy by providing unique, custom automation solutions not available commercially in the marketplace. With experience in a broad range of processes, mechanical design, software, controls, and integration, we offer our customers turn-key solutions specifically engineered for their needs.

Fraunhofer USA CMI solves the challenges of manufacturing high volume consumer products in today's economy by providing unique, custom automation solutions not available commercially in the marketplace. With experience in a broad range of processes, mechanical design, software, controls, and integration, we offer our customers turn-key solutions specifically engineered for their needs. Major challenges in the aerospace industry include the development and manufacturing of complex structures with lightweight materials at low cost. Fraunhofer USA CMI has developed key automation solutions, such as machines to enable manufacturing of custom components made of non-Newtonian fluids, robust techniques to salvage and reshape complex modules, and production equipment for navigation components.

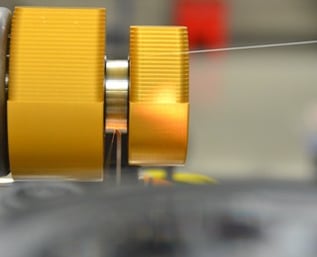

Major challenges in the aerospace industry include the development and manufacturing of complex structures with lightweight materials at low cost. Fraunhofer USA CMI has developed key automation solutions, such as machines to enable manufacturing of custom components made of non-Newtonian fluids, robust techniques to salvage and reshape complex modules, and production equipment for navigation components.  Fraunhofer USA CMI has done extensive work in the development of manufacturing processes and automated assembly machinery for optoelectronic components. Our expertise in this area ranges from high-precision shaping of fiber ends to the development of custom automation equipment for the production of photonic devices. These systems have been deployed for use in telecommunications, sensors, and navigational equipment.

Fraunhofer USA CMI has done extensive work in the development of manufacturing processes and automated assembly machinery for optoelectronic components. Our expertise in this area ranges from high-precision shaping of fiber ends to the development of custom automation equipment for the production of photonic devices. These systems have been deployed for use in telecommunications, sensors, and navigational equipment.